Contested space, small sats, and the gamble on COTS in space

StoryJune 04, 2020

Contested space, where nations compete for military dominance outside Earth’s atmosphere, is driving many military space platforms, but commercial space and small satellites continue to change the way the military suppliers of space electronics approach radiation-hardened component design from testing to deployment.

Contested space, where nations compete for military dominance outside Earth’s atmosphere, is driving many military space platforms, but commercial space and small satellites continue to change the way the military suppliers of space electronics approach radiation-hardened component design from testing to deployment.

Small sats are perhaps the hottest area in space systems today, or at least the most talked-about (maybe along with SpaceX’s launch). Low Earth orbit (LEO) applications are the main playground for small sat designers as they look to launch commercial communications payloads in volume, worrying more about meeting cost and size restrictions rather than the radiation-hardening requirements necessary for higher orbits and military satellites.

The military is also looking for ways to leverage the cost benefits of small sats to deploy technology more quickly as traditional space missions continue; in fact, the need is even more pressing now for the U.S. Department of Defense (DoD), as U.S. adversaries such as China and Russia look to expand their military presence in space.

“Evolving threats such as ballistic missiles and hypersonics and how to counter them are driving a lot of the strategic planning for systems in the military space arena today,” says Tony Jordan, director of business development at Cobham Advanced Electronic Solutions (Colorado Springs, Colorado). “There is a lot of opportunity out there and not just in military applications but in also areas such as the Lunar Gateway and civil space modernization.”

“Contested space is driving this demand for high reliability and product pedigree,” says Josh Broline, director of marketing and applications, Industrial and Communications Business Division at Renesas (Melbourne, Florida). “There have been expectations that the DoD would embrace small sats and commercial technology for space, but we still see more requirements for high-reliability components. U.S. adversaries have raised their game and the DoD wants to maintain its advantage in space, which means more stringent requirements than if there was a push toward commercial small sat technology.

“It is somewhat ironic that as the commercialization of space starts to heat up some are going the other way,” he adds.

Small sat impact

Both traditional, mission-critical, military space missions and commercial small sat applications are growing in number. But the differences in mission profiles, mission life, and radiation requirements can be stark.

“The small sat market is still heavily driven by commercial constellations and in mostly LEO applications,” Jordan says. “Small sat constellations on the military side will have different mission profiles and will be on the smaller side in terms of volume of satellites in the constellation.”

“Most of the demand for these components and COTS [commercial off-the-shelf] in space is on the mega constellations, where you have hundreds to thousands of small sats in individual constellations,” Broline adds.

NASA is also leveraging small sats, or cube sats as NASA officials often term them, for multiple missions including lunar exploration. “A number of things have coalesced to create what is termed the ‘small sat’ and ‘CubeSat’ revolution,” says Christopher Baker, Small Spacecraft Technology program executive within NASA’s Space Technology Mission Directorate. “Part of it has been the availability of commercial off-the-shelf components that have incredible processing power, are very small and function on low electrical power.”

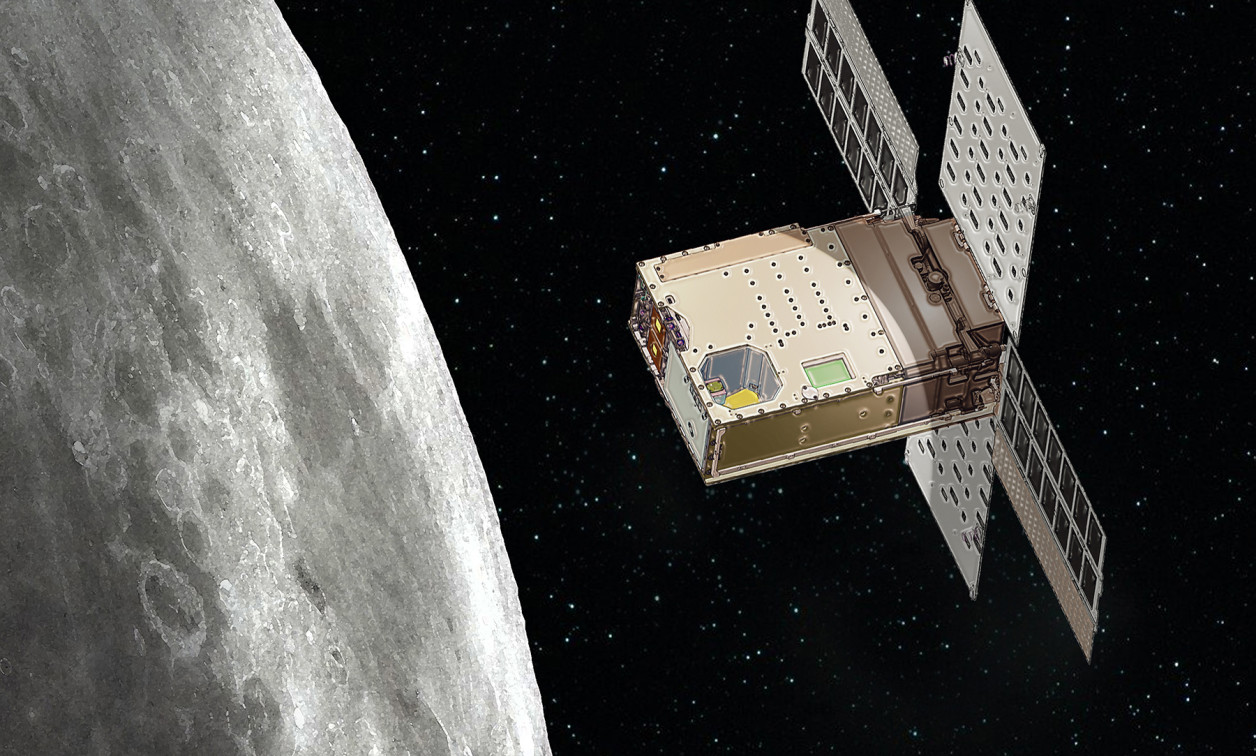

They allow you to do things that previously would not have been possible with a large, monolithic spacecraft, he adds. One planned mission is Lunar Flashlight, a very small six-unit satellite (12 by 24 by 36 centimeters) developed by NASA’s Jet Propulsion Laboratory (Pasadena, California), and NASA’s Marshall Space Flight Center (Huntsville, Alabama). The CubeSat uses an optical receiver aligned with four lasers that sequentially pulse the lunar landscape to look for water ice and other volatiles associated with lunar cold traps.

“[Military platforms] also follow a spiral development plan,” Jordan explains. “For example, having 20 satellites in the first launch, then, as new technology is developed, the launch of the next batch, which also may contain even more satellites. That spiral development of platforms with two- to four-year mission life enables the military to insert more tech, respond to emerging threats, and fix any odd problems they have.”

“We have definitely seen a change the last couple years in terms of small sat proliferation,” says Timothee Dargnies, CEO for 3D-PLUS (San Leandro, California). “At first, those putting up small sats were so focused on volume and keeping costs down that reliability suffered and many of the small sats started to fail. While commercial components may be simple to procure, they are not that simple to upscreen; proper upscreening can be expensive and way more complicated than initially anticipated.”

Gap between commercial and rad-hard

Traditional space suppliers needed to innovate to meet cost restraints while still maintaining necessary radiation resistance. “Systems need a lot of computing capability in a small size with good power efficiency, but a lot of times can’t make that happen with traditional rad-hard technology because of the gap between true rad-hard and commercial component reliability,” Jordan says. “Our LeanRel product enables us to wrap packaging around a high-performance FPGA [field-programmable gate array], for example. These high-performance components are necessary to accomplish critical tasks like tracking hypersonic missiles, or calculating how to intercept a threat in terminal phase. And you can’t do that with all rad-hard products, you need that commercial computing density.”

“Under the LeanRel line we developed a plastic microcontroller that is 14 mm by 14 mm,” he continues. “When you look at plastic versus traditional ceramic hermetic package, the area is the same, but with the volume thickness and weight there is a significant savings as well as a lower price.” (Figure 1.)

![[Figure 1 | Pictured is the LeanREL plastic microcontroller from Cobham Advanced Electronic Solutions that it is targeted at constellation and new space applications. Photo courtesy of Cobham Advanced Electronic Solutions.]](https://data.militaryembedded.com/uploads/articles/authorfiles/images/McHale-Figure_1.jpg)

[Figure 1 | Pictured is the LeanREL plastic microcontroller from Cobham Advanced Electronic Solutions that it is targeted at constellation and new space applications. Photo courtesy of Cobham Advanced Electronic Solutions.]

“The key is to not let that downward pressure from the small sat providers on the price impact reliability in a big way,” says Anton Quiroz, CEO of Apogee Semiconductor (Plano, Texas). “That’s what we drive to do with our processes and flows – still make a reliable product but at a reduced price. Apogee Semiconductor’s TALRAD solution enables this as it changes the layout of the component to reduce the leakage induced by radiation while helping the foundry to improve its process.”

“While military space programs historically required rad-hard-by-design process components for their applications, they are now taking a smarter approach when it comes to defining radiation resistance requirements to allow themselves the use of better performing components,” Dargnies says.

The gamble: COTS in space

COTS continues to be a four-letter word to many in the space electronics community, as the first letter of the acronym represents commercial, which in the rad-hard world means “risk.”

“Actually, COTS in space has been around for many years, back to the early NASA missions,” says Paul Cook, director of Missile Systems, Business Strategy at Curtiss-Wright Defense Solutions (Ashburn, Virginia). “[Its] popularity increased due to the commercial market expansion. Small sat and low-cost solutions drive using COTS with rad-tolerance over rad-hard electronics. An example is using a monitoring system to react to a single-event upset and to promptly recover from it to operate through has reduced overall program cost and schedule when comparing it to a full rad-hard solution.” Curtiss-Wright offers the TTC MWDAU-20XX 20 Mb/sec Miniature Wide-band Data Acquisition Unit for space applications.

“We are also seeing military space guys trying COTS,” Dargnies says. “But you have to be careful when it comes to ensuring the reliability and the usability in space of COTS parts. Our space-qualified modules are mostly based on COTS, but with radiation and reliability guarantees.” 3D PLUS offers the 64Mx72 DDR2 module, which is SEL immune, SEE [single-event effect]-characterized and 100 Krad(Si).

“The use of COTS components is seen as a very risky by some as the impact of radiation on COTS components is unknown, says Malcolm Thomson, president, Radiation Test Solutions (Colorado Springs, Colorado). “One could buy three memory devices from the same lot and from the same company, but find they perform differently when it comes to radiation. You could even find the same date lot code on the packaging of one batch, but discover they are actually from different wafer runs.

“COTS components can represent a gamble,” Thomson continues. “Components in a spacecraft must be consistent and predictable in their radiation performance. For this reason, an area where it would be very risky to use COTS is in the power distribution system. If you lose power to the spacecraft, you likely lose the spacecraft for good.”

Renesas’ Broline agrees: “You don’t want to cut corners to save a few bucks on power management,” he says. “For example, some of our power-management devices directly power mission-critical FPGAs and microprocessors. You do not want to cut corners on your power supply, because you may end up damaging your expensive and mission-critical FPGA and microprocessor due to radiation induced events on the power supply.”

For small sats and launch vehicle applications Renesas offers the ISL71043M/ISL71040M a plastic-packaged, radiation-tolerant PWM controller and GaN FET driver for DC/DC power supplies. (Figure 2.)

[Figure 2 | Pictured is the the ISL71043M/ISL71040M, a plastic-packaged, radiation-tolerant PWM controller and GaN FET driver for DC/DC power supplies. Photo courtesy of Renesas.]

“The mega-constellation manufacturers have driven COTS use, but even they recognize the need to have components qualified to known levels of radiation performance or the satellites can fail and potentially billions lost,” Thomson says. “While the large constellations are made up of what are, in effect, disposable satellites, there are still limits to how disposable. For example, a commercial component with a 5 krad total dose resistance, may work in a certain orbit for, say, one to three years of mission life. However, higher orbits and traditional space applications have a much longer mission life than five years and that component would not be suitable at all.”

The platforms that would use unqualified COTS components also factor in this risk of failure and carry low financial risk. “One year I attended a small sat conference where some panelists were scoffing at a certain constellation provider who said he planned on replacing all his satellites every five years or so, for about $50 billion,” he continues. “But when you do the analysis you realize it made sense, as this provider was planning on delivering internet service to hundreds of millions of people; now $50 billion didn’t seem so large anymore.”

“It comes down to risk management,” Broline says. “If they want to cut corners for cost reasons and leverage COTS parts, they have to upscreen those parts, which means taking on more risk versus using the traditional parts.”

Part of that risk management is maintaining reliability with proper testing and traceability. “For end users they first have to know what is under the hood, particularly what process the IC is built on,” Broline says. “Then they need to know how the reliability testing was done, what kind of field returns, history there may be, etc. Not knowing the component background info can keep system suppliers up at night. Determining what areas to focus more on from a radiation or mechanical perspective is an ongoing effort.”

Testing methods

Testing is everything in the radiation world. Test before you integrate and test before you launch. And the testing methods mostly remain the same. It’s the requirements that are changing.

“The methods, and the physics of course, haven’t really changed in 50 years since we started,” Thomson says. “However, we are seeing quite a bit of work being done on laser-based SEE testing. This is where testers use laser light in short pulses to activate the silicon, similar to that with traditional heavy-ion beams. You can use this technique to screen a part. If it fails under the laser then it is not likely worth performing a heavy-ion test on it. If a part doesn’t fail the laser, then it is a good candidate test using traditional methods.

“We are looking at implementing a laser-based system this year and our small sat business will benefit from it,” he continues. “A small sat manufacturer could leverage the laser scan for, say, three similar components. If one shows upsets you would screen it out, then pick one of the other two and then fully test them. This can save cost and time in the testing process by weeding out less tolerant components.

“The traditional space companies are sticking with rad-hard-by-design and a laser test may not be so useful to them,” Thomson says. “Manufacturers of rad-hard components, however, are interested in laser testing to identify any problems in the early design stages. They can determine the sensitive areas of the silicon design, identify the physical area and device feature causing the upset, and then change the design. Laser-based testing systems have very high-powered lasers; handling that much power through the optics is challenging. This is why these systems have been traditionally used at universities or in research labs. Now, laser testing is becoming a more viable option for commercial environments.”