Returning to shows, SOSA news, supply-chain woes

StorySeptember 30, 2021

Welcome to our 2021 September Resource Guide, which is 100 pages or more for the ninth straight year. Print lives, my friends, especially in the defense electronics community. Thanks again to all our loyal readers and advertisers for your support. More importantly, thank you for supporting our warfighters who sacrifice for all of us every day, especially the 13 who gave their lives during the evacuation of Afghanistan, which is happening as I write this column. We can’t thank them enough.

SOSA news

Our subscribers receiving this issue in their mailbox also received a copy of the 76-page SOSA Special Edition, which marks the release of The Open Group Sensor Open Systems Architecture Technical Standard 1.0. The enthusiasm behind the development of this standard has been remarkable. Please check it out if you haven’t already. If you don’t have a copy, visit us online at https://militaryembedded.com to peruse the first issue of what will be an annual SOSA Special Edition.

SOSA is an example of the Modular Open Systems Approach (MOSA) that U.S. Air Force, Army, and Navy leaders said in 2019 must be an imperative for weapons systems going forward. MOSA is thoroughly explained on page 36 by Nicholas Borton, machine intelligence hardware architect at SRC, in his article titled “MOSA provides the flexibility the DoD needs to modernize the battlespace.”

Returning to shows

The Open Group and the Army are hosting a SOSA/FACE Technical Interchange Meeting in Huntsville in mid-September, several weeks from when I write this. The FACE [Future Airborne Capability Environment] Technical Standard is also managed by the Open Group. That trip will mark my second in-person event in a month, as I attended the Navy League’s Sea Air Space 2021 event in Maryland in early August. “Surreal” was the word many people used to describe attending their first show after 18 months.

Personally, it was wonderful to see so many familiar faces standing in front of me as opposed to remotely through a monitor. Attendees and exhibitors alike were excited to be amongst their colleagues, customers, partners, and even the tech media.

Tech investment

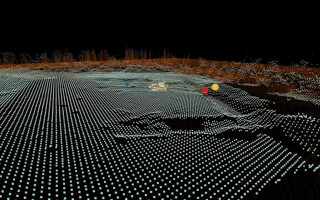

Show attendees were also bullish on funding for defense and naval technology in areas such as hypersonics, hypersonic detection, cybersecurity, and naval radar upgrades. Research on counter-hypersonic weapons draws the most concern, as hypersonics are difficult to track by radar. Frost & Sullivan analysts say that U.S. spending on hypersonic capability rose from $350 million in 2016 to $3.8 billion in 2020.

Countering potential missile threats in the Pacific theater also fuels much of the funding for naval radar upgrades. In her Special Report on shipboard electronics this month, Technology Editor Emma Helfrich covers upgrades to the Aegis SPY-1 radar system and how digitization is critical to the upgrade process. To read her conversations with Raytheon, Lockheed Martin, and Naval Research Laboratory engineers, turn to page 20 for the article titled, “Automation, digitization, & GaN drive shipboard radar upgrades.”

Supply-chain shortages remain

While people are returning to in-person industry events and funding continues to be strong for radar, electronic warfare (EW), and associated technologies, many in the defense community find the global component shortages frustrating, especially when it comes to semiconductors. Lead times for chips are getting longer in every industry, not only in the military.

While military suppliers are skilled at managing end of life (EOL) and obsolete parts, today’s shortages present a different challenge: “COTS [commercial off-the-shelf] suppliers are better suited for typical EOL, long-tail tech sourcing,” Frank Cavallaro, CEO of A2 Global, tells me in the Industry Spotlight article titled “Semiconductor supply chain challenges” on page 44. “The challenge today is the shortages are not just with EOL products, but with current technology. Before the current shortages they were managing a handful of parts in long tail, but now it’s a mix of long tail and current tech and none are getting attention from the supply chain.”

Even as COTS suppliers face new supply-chain challenges, they still have to deliver embedded solutions to the DoD. You can find many of them in our Resource Guide, which starts on page 54, or in the SOSA Special Edition product profile section. Both issues will be at the Association of the U.S. Army (AUSA) annual meeting in October, which my staff and I plan to attend. The SOSA Special Edition will also be distributed at the Association of Old Crows International Symposium and Convention in December in Washington, D.C.

Let’s hope we can keep returning to live events.